Cherry vs Walnut Cutting Board: A Complete Comparison

When choosing between cherry and walnut cutting boards, you’ll notice key differences. Cherry, with a Janka hardness of 950 lbf, offers a fine, uniform grain and superior moisture resistance, resisting warping in humid conditions.

Walnut, at 1010 lbf, provides better wear resistance and shock absorption, ideal for heavy use. Both are gentle on knife edges and darken beautifully over time.

Stick around to uncover deeper insights into their unique benefits and care needs.

Key Takeaways

- Cherry offers superior moisture resistance with a fine, closed grain, while walnut is more porous and denser.

- Walnut has a slightly higher Janka hardness (1010 lbf) than cherry (950-995 lbf), providing better durability.

- Cherry darkens to a rich reddish-brown, whereas walnut lightens slightly, revealing honey tones over time.

- Walnut’s grain is wavy or curly with bold contrasts; cherry’s is straight and uniform for subtle elegance.

- Both are knife-friendly due to moderate hardness, with end-grain construction reducing blade wear.

Hardness and Durability Comparison

When comparing the hardness of cherry and walnut cutting boards, you’ll notice that walnut edges out cherry with a Janka hardness rating of approximately 1010 lbf, compared to cherry’s rating of about 950 lbf, occasionally cited as high as 995 lbf.

Walnut slightly surpasses cherry in hardness, boasting a Janka rating of 1010 lbf against cherry’s 950-995 lbf for cutting boards.

This slight difference means walnut offers better resistance to wear and tear, making it less prone to dents over time.

Both woods fall within the ideal hardness range of 900-1500 lbf for cutting boards, ensuring durability.

As you assess durability, you’ll find both cherry and walnut are robust hardwoods. For context, walnut’s durability can be contrasted with acacia’s extreme density, which exceeds walnut in hardness ratings.

Walnut’s higher density enhances its resistance to surface damage, while cherry, though slightly softer, holds up well, especially in end-grain construction.

Additionally, walnut’s ability to absorb shock well contributes to its long-term durability in demanding kitchen environments absorb shock well.

Knife Edge Compatibility

Let’s shift focus from hardness and durability to how cherry and walnut cutting boards impact your knife edges.

You’ll find that both woods, with Cherry at 950 lbf and Walnut at 1010 lbf on the Janka scale, are softer than harder options like Maple (1450 lbf), making them gentler on your blades.

Unlike bamboo boards, whose density may dull knives quicker than softer woods, cherry and walnut offer a more blade-friendly surface.

Opt for end-grain construction if you’re prioritizing knife longevity; the vertical fibers let your knife slide between them, reducing wear compared to edge-grain, where you cut across horizontal fibers, dulling edges faster.

End-grain also offers self-healing, closing up after cuts for a smoother surface. This design further enhances kitchen safety by reducing slip risks with maintained blade sharpness.

Visual Appeal and Color Changes

Explore into the visual allure of cherry and walnut cutting boards, where their distinct initial appearances set the tone for kitchen aesthetics.

You’ll notice cherry starts with a light pinkish-brown hue, exuding warm, reddish undertones and a moderate luster, ideal for classic or rustic designs.

Walnut, in contrast, offers a sophisticated range from pale to deep chocolate brown, often with purplish hints and striking light-dark contrasts, suiting modern styles.

Walnut captivates with a refined palette of pale to deep chocolate brown, accented by purplish hues and bold contrasts, perfect for modern elegance.

Over time, cherry darkens to a rich reddish-brown, gaining a lustrous patina, though uneven light exposure can vary results.

Walnut slightly lightens, retaining its dark essence while revealing honey tones and a refined patina with care.

Regular oiling preserves their evolving colors, and your preference—warm evolution or dark elegance—guides the choice. For optimal protection and enhancement, consider using food-grade mineral oil regularly.

This transformation in cherry is most noticeable within the first six months of exposure to light and oxygen first six months.

Grain Patterns and Textures

As you examine cherry and walnut cutting boards, you’ll notice cherry’s smooth grain stands out with its primarily straight, fine, and uniform pattern, offering a subtle, closed-pore texture.

In contrast, walnut’s varied texture catches your eye with its medium coarseness, open pores, and often irregular, wavy, or curly grain that adds intricate character.

These visual pattern differences—cherry’s understated consistency versus walnut’s dramatic figuring—play a key role in determining the board’s aesthetic and tactile appeal.

Additionally, cherry’s grain can sometimes showcase occasional waves or curls, adding a touch of unique design to each board, while walnut’s intricate patterns echo the elegant grain seen in other hardwoods for enhanced durability.

Cherry’s Smooth Grain

Notice the refined elegance of cherry wood’s grain when you examine a cutting board crafted from this material.

You’ll see a fine, straight pattern with a smooth, satiny texture, thanks to its closed-grain structure akin to maple. Due to its properties, cherry wood is often featured in durable hardwood options for boards that balance aesthetics and functionality.

This uniform grain, often with subtle waves or figured curls, boasts a natural luster that enhances its rich, reddish-brown hue, deepening with age and light exposure.

As you work with it, you’ll appreciate how the tight grain resists water and stains moderately while remaining hygienic.

Its softer nature compared to harder woods is gentler on knife edges, reducing dulling.

Additionally, cherry wood’s ease of workability makes it a favorite for crafting cutting boards with precision and uniform coloring.

Sanding yields a seamless finish, ideal for clear coats that highlight the grain’s beauty, though you’ll need regular maintenance to prevent scarring ease of workability.

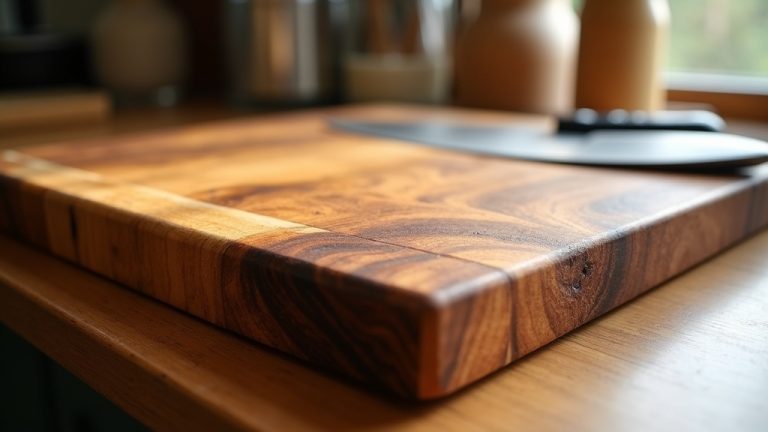

Walnut’s Varied Texture

Walnut’s fascinating texture sets it apart as you explore a cutting board made from this hardwood. You’ll notice its generally straight, fine grain, often interrupted by waves, curls, or swirls that add character.

Its medium, somewhat coarse feel and moderate natural sheen enhance its appeal. Figured patterns like burl, with mesmerizing swirls, or crotch, with wrinkled Y-shaped fibers, make each piece unique. Additionally, walnut develops a lustrous patina over time, enriching its aesthetic value as it ages.

Check this detailed breakdown of walnut’s grain variations:

| Pattern | Description | Rarity |

|---|---|---|

| Curl | Tight, rippling effect | Common |

| Burl | Intricate swirls from stress | Rare, valued |

| Crotch | Wrinkled, Y-shaped fibers | Occasional |

| Wave | Smooth, rhythmic curves | Common |

| Knots | Natural irregularities | Frequent |

You’ll find walnut’s density (610 kg/m³) and workability ideal, though figured grains challenge planing. Sand and finish it for a smooth, lasting surface. This process ensures a hygienic surface, similar to the naturally resistant qualities of rubberwood.

Visual Pattern Differences

Let’s shift focus from walnut’s unique texture to a broader comparison of visual pattern differences between cherry and walnut for cutting boards.

You’ll notice cherry’s fine, straight, closed grain offers a smooth, uniform look, often with subtle curls or pith flecks, achieving a satiny finish when sanded.

In contrast, walnut’s grain, while mostly straight, can turn wavy or curly, presenting a coarser, medium texture with prominent, irregular patterns like burls or knots.

Cherry’s patterns stay subdued, while walnut’s bolder, varied figures stand out with greater contrast.

You’ll see cherry’s uniform pinkish-brown darken to reddish-brown over time, whereas walnut’s spectrum, from pale brown to dark chocolate, shows striking variation even within one board.

Proper sealing, such as using tung oil, can further accentuate these visual differences by enhancing the wood’s natural grain and texture for better durability.

Maintenance Needs and Care Tips

Proper maintenance of your cherry or walnut cutting board guarantees its longevity and keeps it safe for food preparation. After each use, wash it with mild soap and warm water, scrubbing gently with a soft cloth.

Rinse both sides thoroughly, then towel dry immediately. Stand it upright to air dry in a well-ventilated area, away from heat or sunlight. Don’t use a dishwasher or soak it, as this causes damage.

Season your board with food-grade mineral oil monthly or when it looks dry, letting it soak for hours before wiping off excess. This process enhances resistance to scratches and stains, similar to resealing marble boards.

For stains, scrub with a baking soda paste; for odors, use lemon juice or vinegar. Avoid harsh cleaners, and sand light scratches with fine-grit paper, re-oiling afterward. Additionally, designate separate boards for different food types to prevent cross-contamination.

Moisture Resistance and Porosity

As you evaluate cherry and walnut cutting boards, understanding their moisture resistance and porosity is essential for making an informed choice.

Cherry wood boasts a fine, closed grain structure, offering superior moisture resistance with its tight, smooth, semi-ring-porous nature.

It resists warping and shrinking in humid conditions, though it’s sensitive to prolonged water exposure.

Walnut, with its denser yet slightly more porous semi-ring-porous grain, still provides good water resistance due to its tight structure, but it may need more frequent oiling to prevent moisture penetration.

When comparing them, cherry’s tighter grain gives it a slight edge in resisting moisture over walnut.

Both hardwoods are suitable for cutting boards, outperforming more open-pored woods in damp environments, and their medium porosity allows for effective sealing with proper maintenance. To further enhance their moisture resistance, regular application of food-safe mineral oil is advised.

Natural Antimicrobial Benefits

As you evaluate cutting boards, consider how wood naturally resists bacteria, with hardwoods like cherry and walnut showcasing impressive antimicrobial properties through their ability to absorb moisture and trap pathogens below the surface.

You’ll notice walnut stands out due to juglone, a unique compound that enhances its protective effect against bacterial growth, often surpassing cherry in efficacy.

Keep this in mind as you weigh hygiene alongside other factors in your choice between these materials.

Additionally, proper maintenance of these wooden boards, such as regular cleaning and oiling, ensures long-term safety against bacterial contamination.

Moreover, these boards offer an added advantage by safeguarding knives from the dulling effects of harder surfaces like granite countertops.

Wood’s Bacterial Resistance

While many might assume plastic cutting boards are more hygienic, wood’s natural bacterial resistance offers a surprising advantage due to its unique structural and chemical properties.

You’ll find that wood’s porous nature uses capillary action to pull bacteria deep into its fibers, trapping them and preventing surface multiplication. Its hygroscopic quality absorbs moisture, desiccating bacteria and inhibiting growth.

Additionally, wood cutting boards, especially hardwoods, contain natural compounds like tannins that inhibit bacterial growth.

Check this comparison of wood’s antimicrobial traits:

| Wood Type | Key Antimicrobial Compound | Effectiveness |

|---|---|---|

| Cherry | Tannins, Natural Oils | Moderate Resistance |

| Walnut | Dense Structure, Compounds | High Resistance |

| Maple | Natural Enzymes | Strong Resistance |

Moreover, hardwoods like cherry and walnut boast closed-grain structures, reducing bacterial survival compared to plastic, where knife scars harbor germs.

Juglone’s Protective Effect

Notice how juglone inhibits key enzymes and mitochondrial electron transport in pathogens, curbing their growth.

In walnut wood, especially black walnut, juglone levels are higher, though drying reduces them in cutting boards.

Rest assured, properly processed walnut boards are generally food-safe, with minimal juglone in heartwood, offering subtle antimicrobial benefits without risk.

Additionally, juglone’s natural presence in walnut contributes to its antimicrobial properties, providing an eco-friendly defense against bacteria and fungi.

Price Differences and Value

How do the costs of cherry and walnut cutting boards stack up when you’re weighing their value?

You’ll notice walnut boards consistently cost more, often priced as a premium option at $8-$16.50 per board foot, compared to cherry’s mid-range $6-$7.50.

This gap stems from raw material costs and walnut’s luxurious dark grain, elevating its perceived worth over cherry’s warm, classic reddish hue.

Consider these value factors when choosing:

- Walnut’s higher cost reflects its “statement piece” aesthetic appeal.

- Cherry offers comparable durability (Janka: ~950 lbf vs. Walnut’s ~1010 lbf).

- Construction, like end grain, spikes prices for both woods.

- Thickness and dimensions heavily influence overall expense.

- Maintenance dictates long-term value, not just initial price.

- Walnut’s scarcity drives up raw material costs due to limited availability of mature trees.

Availability and Sourcing Factors

Diving into the availability and sourcing of cherry and walnut for cutting boards, you’ll find distinct regional and supply dynamics at play.

Cherry thrives in the eastern US, especially the Allegheny Plateau, with Pennsylvania and New York as key suppliers, though quality can fluctuate due to environmental factors.

Walnut, less abundant, dominates central US hardwood forests, with high global demand straining supply for premium, wide boards.

Notably, cherry’s native range extends from southeastern Canada to eastern Texas, aligning with its prevalence in the eastern US southeastern Canada range.

Here’s a snapshot of sourcing factors:

| Aspect | Cherry | Walnut |

|---|---|---|

| Native Range | Eastern North America | Eastern/Central North America |

| Key Sourcing States | PA, NY, VA, WV | OH, IA, central states |

| Supply Challenges | Cyclical, disease susceptibility | Limited, high demand, narrower boards |

Choosing the Right Option for You

Why settle for just any cutting board when you can pick one tailored to your needs?

When choosing between cherry and walnut, consider your priorities in the kitchen with these critical factors:

- Hardness: Walnut’s 1000-1010 lbf Janka rating offers better wear resistance; cherry’s 950 lbf may show knife marks sooner.

- Knife Care: Cherry’s softer grain is gentler on edges; walnut might dull blades slightly faster.

- Maintenance: Walnut’s porosity demands frequent oiling; cherry needs care for scoring.

- Aesthetics: Walnut’s dark, elegant tones suit modern kitchens; cherry’s warm, reddish hues fit rustic vibes.

- Properties: Walnut’s stronger antimicrobial juglone edges out cherry’s weaker defenses.

Additionally, remember that cherry’s heartwood starts light pinkish brown but darkens over time with exposure to light, enhancing its aesthetic appeal.

Evaluate these specs against your cooking habits and style to decide.

Frequently Asked Questions

Can Cherry or Walnut Boards Be Personalized?

Hey, you’re wondering if wooden cutting boards can be personalized, right?

You’ll be glad to know they absolutely can!

Opt for laser engraving to carve precise names, dates, or intricate designs into the wood.

You can also explore wood inlay for a unique touch with contrasting colors.

Customization options include size, thickness, and features like juice grooves.

Each board becomes a one-of-a-kind piece with personal flair!

Are Walnut Boards Heavier Than Cherry Ones?

Hey, you’re wondering if walnut boards tip the scale more than cherry ones.

Let’s break it down with precision.

Walnut’s density averages 610-640 kg/m³, while cherry sits at 534-580 kg/m³.

Board foot estimates peg walnut at 3.3-3.5 lbs, compared to cherry’s 3.0-3.3 lbs.

With walnut’s higher Janka hardness of 1010 lbf versus cherry’s 950 lbf, you’ll notice walnut consistently weighs more for identical dimensions.

Do Cherry Boards Smell Different From Walnut?

Imagine, by sheer coincidence, walking into a workshop just as a craftsman slices into fresh wood, the air blooming with distinct aromas.

You’ll notice cherry boards often exude a sweet, fruity scent, reminiscent of ripe cherries or almonds, while walnut’s odor is milder, sometimes nutty or musky, though occasionally unpleasant if the log’s condition varies.

Technically, cherry’s volatile oils create a stronger, sweeter profile compared to walnut’s fainter, woodsy notes.

Is Walnut or Cherry Better for Gifting?

When choosing a wood for gifting, you’ll need to weigh aesthetics and functionality with precision.

Opt for walnut if you’re aiming for a luxurious, deep brown elegance that hides stains well and offers strong antimicrobial properties.

Choose cherry if you prefer warm, reddish tones that enrich over time and pair beautifully with kitchen decor.

Both are durable, but match the recipient’s taste and style for the perfect gift.

Can Either Wood Type Cause Allergies?

Like a hidden thorn in a rosebush, allergies from wood can prick you unexpectedly.

You’ve gotta know that certain woods trigger reactions—think dermatitis, wheezing, or sinus flare-ups from dust exposure.

Sensitizers in wood can worsen symptoms over time, impacting your skin or lungs with redness, itching, or shortness of breath.

Even finished products aren’t fully safe; residues linger.

Always check wood profiles and clean meticulously to minimize risks.

Cut to the Chase: Your Perfect Cutting Board Awaits

As you decide between cherry and walnut cutting boards, consider their unique strengths. Did you know walnut boasts a Janka hardness rating of 1,010 lbf, compared to cherry’s 950 lbf, making it slightly more durable against wear?

Weigh this durability against your aesthetic and maintenance preferences. Choose based on your kitchen’s demands—walnut for longevity or cherry for a warmer tone. Make the precise choice that aligns with your cutting needs.