Real vs Fake Damascus Steel: Spot the Difference

You’ll spot real Damascus steel by its durable layered microstructure formed through precise forge-welding, folding, and thermal cycles that create distinct carbide bands and anisotropic fracture patterns.

Genuine blades feature intricate, naturally etched patterns with visible lamellae extending beyond surface decorations.

In contrast, fakes show uniform, surface-only designs that polish away. Authentic Damascus also exhibits micro-folds and chemical markers like vanadium-induced carbides.

Understanding these technical distinctions will clarify the craftsmanship and performance behind authentic Damascus steel.

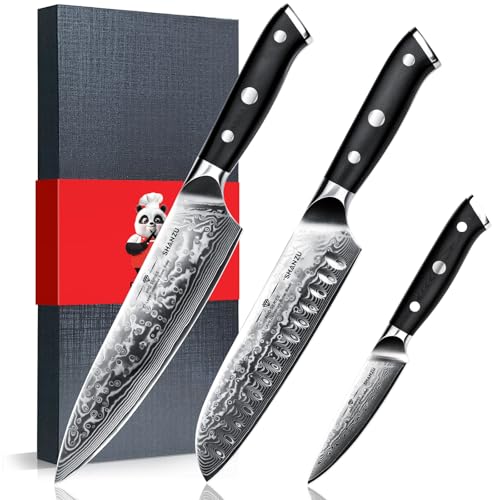

- Japanese Steel Knife Core, Super Sharp: SHAN ZU chef’s knife core is made of 10Cr15Mov Damascus…

- REAL Damascus Knife, not Lazer Etched: SHAN ZU Damascus chef knife layering sheets of carbon steel,…

- A total of 67 Layers Steel, Long-Lasting Use: SHAN ZU Damascus chef knife forged by 67 layer sheets…

Key Takeaways

- Real Damascus (wootz) steel features distinctive carbide nanowire microstructures and dendritic patterns absent in fake or pattern-welded steels.

- Authentic Damascus shows inhomogeneous carbide bands and Widmanstätten structures formed from crucible steel processes, unlike uniform layering in fakes.

- Fake Damascus often uses layered or pattern-welded steels with repeated folding and etching to mimic patterns without original microstructural markers.

- Genuine Damascus blades have very low impurities and carbide-forming elements like vanadium and molybdenum influencing pattern and fracture behavior.

- Acid etching reveals authentic Damascus patterns formed by carbide segregation, while fake Damascus patterns result mainly from surface layering and manipulation.

Quick Comparison Table: Real vs Fake Damascus Steel

| Feature | Real Damascus Steel | Fake Damascus Steel |

|---|---|---|

| Microstructure | Carbide bands, nanowires, Widmanstätten patterns | Uniform layers, no carbide segregation |

| Pattern Origin | Internal lamellae from forge-folding | Surface etching only, polishes away |

| Etching Response | Patterns re-emerge after polish | Patterns disappear permanently |

| Fracture Pattern | Anisotropic, folded interfaces | Homogeneous, brittle failure |

| Elements Present | Vanadium/molybdenum carbides | Lacks specific impurity markers |

| Durability | 740 MPa yield strength, tough layers | Weaker welds, inconsistent performance |

Origins and Historical Background of Damascus Steel

Although Damascus steel is often associated with the Syrian city, its origins trace back to Southern India around 300 BC.

Damascus steel, famed for its strength, originally emerged from Southern India around 300 BC.

Wootz steel was first produced using crucible smelting with carbon-rich materials. This process led to the formation of a protective oxide layer on the metal surface, which contributed to its durability.

You’ll find early wootz blades dating from the first century BC, crafted in Indian regions like Golconda, Telangana, and Tamil Nadu.

The process involved forming a high-carbon alloy in sealed crucibles, enabling precise control over carbon content.

From the 3rd century onward, India exported wootz ingots to the Near East, including Persia and Syria.

There, blacksmiths refined them into Damascus blades. While the name derives from Damascus due to trade and forging centers there, the original metallurgical technique and material production were distinctly Indian.

This formed the foundation of what later became known as Damascus steel, a material whose secret strength is attributed to the presence of carbide nanowires and nanotubes.

True Damascus steel has not been successfully reproduced since around 1800 A.D.

Visual and Microstructural Characteristics

Have you ever noticed those beautiful patterns in genuine Damascus steel? They come from a layered forging process that creates unique microstructures. When you look at them under magnification, you can really see the differences in the crystalline formations and how the carbon is distributed.

These microstructural differences aren’t just for show, either. They actually play a significant role in the steel’s visual complexity and overall performance.

Plus, when acid etching is applied, it highlights those authentic patterns by bringing out the natural light and dark contrasts. This is a key factor that sets real Damascus steel apart from the uniform appearance often found in imitations.

To preserve these intricate designs, it is essential to apply protective oils after cleaning to maintain both the blade’s aesthetic and its corrosion resistance.

Pattern Origins

When you examine Damascus steel patterns, their origins lie in the intricate processes of layering, manipulating, and etching different steels to create distinctive visual and microstructural characteristics.

By alternating steels with varied carbon and alloy contents, artisans forge-weld, fold, twist, and manipulate billets to generate macroscopic motifs like ladder, twist, or mosaic patterns. Proper sharpening techniques emphasize maintaining these layered patterns to preserve the blade’s unique aesthetic and structural integrity, especially when using fine grit stones.

Acid etching reveals these patterns by differentially corroding steels based on chemical composition and surface topography.

Mechanical methods such as stacking, punching, and re-stacking rearrange internal layers to form complex designs.

Key aspects include:

- Layer manipulation techniques (folding, twisting, cutting) define pattern geometry.

- Acid etching enhances contrast by exploiting steel chemistry differences.

- Mechanical rearrangement creates intricate mosaic and miter patterns.

- The original Damascus steel derived from ancient wootz steel known for its distinct “watered” pattern and high-carbon content.

These factors collectively produce authentic, enduring Damascus surface patterns.

Microstructure Differences

Because microstructure governs both the aesthetic and mechanical properties of Damascus steel, examining the lamellar arrangements, carbide characteristics, and matrix features reveals critical distinctions between authentic and fake specimens.

Genuine Damascus displays alternating hard and soft lamellae with variable thicknesses and mechanical bonding, often interrupted or folded, unlike the uniform, poorly welded layers in fakes. Crucible Damascus (wootz) identification cannot rely on a single criterion; multiple characteristics must be considered, including dendrite formation and elemental segregation typical of crucible steel microstructure. The presence of elements such as vanadium and molybdenum can influence the carbide morphology significantly.

Carbide morphology in real samples ranges from coarse cementite islands to needle-like Widmanstätten structures, clustered along lamellae, contrasting the homogenized, uniformly dispersed carbides in imitations.

The matrix in authentic steel features fine pearlite spacing and sometimes cold-worked troostite, enhancing strength and hardness. This fine microstructure is comparable to what is found in high-quality steels like VG10 steel that balance hardness and toughness for superior performance.

These microstructural signatures, anisotropic fracture paths, heterogeneous carbide chemistry, and fine-grained matrices serve as definitive markers, allowing you to differentiate true Damascus steel from modern reproductions with confidence.

Etching Effects

The distinctive microstructures of authentic Damascus steel directly influence its response to acid etching, revealing patterns that are both visually striking and structurally informative.

When you etch real Damascus, the layered metals react selectively, restoring the intricate wavy pattern even after polishing.

This process is achieved through pattern layer welding, where alternating steel sheets with different carbon contents are stacked and forged to create the characteristic layered structure. Such layering is somewhat analogous to how steels like AUS-10 toughness are engineered for specific mechanical properties by blending elements.

Fake Damascus, by contrast, loses its surface-applied design permanently upon polishing, as it lacks genuine layered structure.

Key differences include:

- Pattern Clarity: Real Damascus shows delicate, natural alternating light and dark patterns; fakes appear blurry or overly perfect.

- Color Contrast: Real blades exhibit bright, contrasting hues from high-carbon and nickel layers; fakes have uniform, dull coloration.

- Surface Texture and Consistency: Real Damascus feels slightly uneven with patterns extending across all surfaces; fake patterns are smooth and limited to blade faces only.

These etching effects are definitive markers of authenticity.

Traditional Manufacturing Techniques

Did you know that traditional Damascus steel is made using two main methods? First up is the crucible steel process. This is where wootz ingots come into play, and they develop these really cool carbide structures.

Then there’s pattern-welding. This method layers together steels with different carbon contents to create those beautiful, distinct patterns we often associate with Damascus steel. The layering process typically involves stacking and folding the steels multiple times to increase the number of layers and enhance pattern complexity. This technique allows for precise control over the blade’s geometry and pattern.

Now, if we jump to modern times, stainless Damascus has adapted these traditional techniques. It combines various stainless steels to not only enhance corrosion resistance but also to provide that eye-catching visual contrast.

Crucible Steel Process

When exploring traditional manufacturing techniques for Damascus steel, you’ll find crucible steel processes at the core, rooted in ancient methods that controlled carbon content and microstructure through careful thermal and chemical management.

Originating from South Asia’s wootz steel, this process involves melting or carburizing iron in sealed crucibles to achieve specific carbon levels, vital for the characteristic patterns and mechanical properties. The resulting steel often exhibited an inhomogeneous composite structure of varying carbon content, contributing to both durability and distinctive surface patterns. These properties are enhanced by the presence of carbide-rich microstructures that influence toughness and wear resistance.

Key aspects include:

Carbon control: Varied methods produced steels with 1.0–1.5% carbon, forming carbide bands vital for patterning.

Alloying and fluxes: Elements like manganese and added fluxes refined the melt, removed impurities, and influenced forging behavior.

Thermal practice: Refractory crucibles and precise heating protocols guaranteed homogenization and minimized defects, similar to the controlled austenitization temperatures used in modern steels like VG10 and SG2.

This crucible steel foundation differentiates authentic Damascus from imitations, emphasizing metallurgical precision over superficial patterning.

Pattern-Welding Method

By carefully selecting and preparing steel plates of varying carbon contents, pattern-welding achieves a balance between edge hardness and structural toughness.

You start with high, low, and intermediate carbon steels, often mixing high-carbon with nickel-alloy steel for performance and aesthetics.

After cleaning the plates, you stack 5-7 layers, tack-weld the ends, and heat them to around 1300°F in a low-oxygen environment using anhydrous borax flux to prevent oxidation. This process is critical to ensure the microstructure refinement that enhances blade durability.

You then forge-weld under intense heat and pressure, repeatedly folding, cutting, restacking, and rewelding to multiply layers and refine the pattern.

Various manipulations, such as twisting, chiseling grooves, or dimpling, create distinctive patterns. The final blade requires polishing and acid etching to reveal the intricate patterns formed by the layered steels acid etching.

Finally, you polish and etch the blade in acid to reveal the layered structure, highlighting the contrasting steel bands that define true pattern-welded Damascus.

Stainless Damascus Techniques

Mastering stainless Damascus techniques hinges on controlling oxidation during forge welding. Stainless steels form chromium oxide layers that hinder weld quality. Proper cleaning and drying of materials before welding are essential to prevent early oxidation and ensure strong welds.

You’ll need to use sealed stainless steel canisters (“canning”) with TIG or MIG-welded seams to exclude oxygen and prevent weld failure. Selecting compatible stainless alloys, commonly combining 300-series with high-carbon 400-series or powder-metallurgy grades, ensures both weldability and pattern contrast. The use of powder metallurgy steels is preferred for carbon-loaded stainless Damascus blades due to their negligible porosity and fine grain structure.

Precise temperature control is critical. Overheating causes chromium depletion and grain growth, degrading weld integrity. After forging, applying a thin layer of food-grade oil helps protect the billet from moisture and oxidation during cooling.

Key considerations include:

- Utilizing argon-purged sealed cans to maintain an inert atmosphere.

- Preparing and cleaning surfaces meticulously before stacking.

- Employing multiple controlled heats and gentle forging to avoid layer slippage.

These steps collectively optimize weld strength and pattern clarity in stainless Damascus billets.

Modern Pattern-Welded Damascus Production

To kick off modern pattern-welded Damascus production, you start by carefully selecting steels with varying carbon contents and alloying elements to balance hardness, malleability, and visual contrast.

High-carbon steels provide edge retention, while low-carbon steels add ductility and pattern contrast. This method mimics the historical approach where alternating carbon-rich and carbon-poor layers contributed to the distinctive patterns and mechanical properties of the steel. Using steels with vanadium carbides can further improve wear resistance and edge stability in the final blade.

You stack alternating layers, then forge-weld them at 1,200–1,300°C using flux to prevent oxidation.

After initial welding, you repeatedly fold and draw out the billet, multiplying layers to enhance pattern complexity and carbon distribution. Next, you forge and shape the billet, reheating as needed to avoid delamination and maintain profile integrity.

Finally, you normalize, quench, and temper the blade, then use acid etching to reveal the layered pattern before polishing and sharpening. This precise sequence assures authentic modern Damascus with peak performance, much like the historical blades whose patterns resemble flowing water.

Stainless Damascus and Contemporary Variants

Combining at least two stainless steels with chromium contents exceeding 14%, Stainless Damascus offers corrosion resistance alongside the distinctive layered patterns traditional Damascus is known for.

You’ll find these steels often martensitic, blending toughness and high hardness with excellent edge retention. The patterns emerge through acid etching, which differentiates layers by oxidation rates. The presence of chromium in amounts greater than 10.5% is what classifies these steels as stainless steel, providing superior rust resistance compared with other alloy steels.

Contemporary variants utilize powder metallurgy and Hot Isostatic Pressing to create homogenous, impurity-minimized structures without traditional folding.

Key features include:

- Chromium-rich layers form a protective oxide film, enhancing corrosion resistance.

- Carbon and vanadium refine hardness and toughness via carbide formation.

- Advanced alloys like RWL 34 and PMC27 enable superior cutting performance.

This approach yields stainless Damascus steel that balances aesthetics, durability, and cutting efficiency for modern applications.

Laboratory Methods for Damascus Fabrication

Understanding the characteristics of stainless Damascus and contemporary variants provides a foundation for replicating these steels in controlled settings. You’ll use controlled-atmosphere furnaces with ceramic-fiber linings to maintain forge-welding temperatures above 1200°C. Employing inert gases or reducing atmospheres and borax flux prevents decarburization and promotes diffusion bonding.

Selecting binary steel pairs like AISI 1095 and 15N20 guarantees weldability and pattern contrast. Powder metallurgy combined with hot isostatic pressing achieves homogeneous layers with minimal porosity. You’ll stack, weld, cut, and restack plates, producing 30–120 layers, applying precise forge-welding protocols, mechanical patterning, and standardized etching to reveal lamellar contrast.

Temperature monitoring with thermocouples and PID controllers maintains critical thermal cycles, replicating historical thermal histories and microstructures essential for authentic pattern development. Achieving the distinctive damascene patterns relies on controlling carbide-forming impurities at very low levels, such as vanadium and molybdenum, which promote carbide band formation crucial for authentic wootz steel replication.

Identifying Genuine Damascus Steel

When you examine Damascus steel, discerning genuine layered construction from surface imitations hinges on recognizing distinctive visual and structural cues.

You need to analyze pattern integrity, edge characteristics, and cross-sectional evidence critically. Authentic Damascus reveals flowing, organic patterns with smooth shifts between light and dark bands, consistent throughout the blade, including tang and spine. This craftsmanship reflects the exceptional sharpness and durability that genuine Damascus steel is historically known for.

Surface-only patterns typically lack such continuity. Under magnification, real weld-folded interfaces display micro-fold structures absent in fakes. Cross-sections show visible lamination and differential corrosion patterns, confirming internal layering.

Key identifiers include:

- Pattern permanence: true layered steel re-emerges after polishing and acid re-etching, unlike surface-etched fakes.

- Edge geometry: subtle, non-uniform grind marks indicate hand forging.

- Layer consistency: uniform layer thickness and count along blade length denote genuine forge welding.

These analytical criteria guide you in authenticating Damascus steel effectively.

Mechanical Properties and Performance Considerations

Although Damascus steel‘s aesthetic appeal is often highlighted, its mechanical properties critically define its real-world performance.

You’ll find Damascus boasts an average yield strength of 740 MPa and tensile strength of 1070 MPa, surpassing typical hot-rolled 1.0% carbon steels.

Its layered forging technique enhances tensile durability beyond individual steels alone. The distinct layering can reduce toughness in some directions due to crack propagation along elongated inclusions and carbide stringers, showing an anisotropic toughness behavior.

Hardness values range from 40 to 62 HRC depending on steel types and heat treatment, with high-carbon cores resisting scratches effectively.

Impact toughness varies by fold count and band orientation, reaching up to 5.49 J/cm² in 250-fold samples, where perpendicular impact strength exceeds parallel due to crack deflection at lamination interfaces.

While modern steels may offer superior corrosion resistance and lighter weight, genuine Damascus combines constituent properties, delivering superior strength and toughness balanced by anisotropic effects inherent in its layered structure.

Guidance for Buyers and Authentication Practices

Because authentic Damascus steel commands a premium, you need to employ rigorous authentication practices before purchase.

Authentic Damascus steel demands thorough verification to ensure genuine craftsmanship and avoid costly counterfeits.

Start by scrutinizing the blade’s pattern continuity; genuine Damascus shows consistent patterns across edges and tang, unlike surface-etched fakes.

Verify maker credentials and provenance; reputable smiths provide serial numbers, certificates, and verifiable documentation.

Employ simple in-shop tests such as the tap sound test, which reveals layered construction through a clear ringing tone.

Examine the pattern under magnification and varied lighting for organic shifts and depth.

Confirm provenance via certificates and cross-check origin against known timelines.

Use tactile inspection and localized polish tests to distinguish structural patterns from surface decorations.

These analytical steps minimize counterfeit risk and guarantee a valid investment in authentic Damascus steel.

Frequently Asked Questions

Can Damascus Steel Blades Be Safely Used for Food Preparation?

Yes, you can safely use Damascus steel blades for food preparation if you follow strict maintenance protocols.

You’ll need to hand-wash them promptly, dry thoroughly, and apply food-safe mineral oil to prevent rust.

Avoid dishwashers and prolonged moisture exposure, as high carbon content increases corrosion risk.

With proper care, these blades offer exceptional sharpness and precision, making them suitable for kitchen use despite requiring more vigilance than stainless steel knives.

How Should I Care for and Maintain a Damascus Steel Knife?

You should clean your Damascus steel knife by rinsing with warm water and mild soap, avoiding abrasive materials and dishwashers.

Dry it thoroughly with a soft cloth immediately after washing, focusing on all areas.

Apply a thin layer of food-grade mineral oil or Renaissance Wax to prevent rust.

Sharpen monthly if used daily, honing regularly.

Remove rust gently with fine steel wool or water stones, maintaining edge sharpness for peak performance and durability.

Are There Health Risks Associated With Handling Etched Damascus Steel?

Imagine a chef who constantly handles etched Damascus knives without properly drying them. Over time, the acidic residues and moisture cause corrosion and potential nickel leaching.

Yes, there are health risks linked to handling etched Damascus steel. You risk exposure to toxic nickel alloys and corrosive etching chemicals, which can transfer to food or your skin.

Always dry blades immediately post-use and avoid abrasive cleaners to minimize corrosion and chemical exposure.

What Are the Environmental Impacts of Damascus Steel Production?

You’ll find that Damascus steel production impacts the environment through significant CO2 emissions during steelmaking and mining-related habitat disruption.

Pattern-welding uses heat and energy-intensive processes, generating waste like slag and acidic residues.

Chemical etching and finishing release hazardous substances needing proper disposal.

Small-scale artisans often lack emission controls, increasing local pollution.

However, using recycled steel reduces raw material demand and embodied energy, mitigating some upstream environmental burdens.

Can Damascus Steel Be Repaired or Reforged Without Losing Its Pattern?

Sure, you can totally slap your Damascus steel on a forge and expect it to come out looking like a magic zebra without a care.

But seriously, repairing or reforging it requires finesse: small defects can be rewelded carefully, and controlled heat treatments preserve the layered pattern.

Excessive grinding or overheating risks destroying the intricate lamellar layers, so you’ve got to balance defect removal and pattern retention meticulously to keep that signature contrast crisp.

Unlock Authentic Damascus Steel: Your Next Blade Hunt

When distinguishing real Damascus steel from imitations, you’re not just looking at patterns. You’re decoding history and metallurgy intertwined.

Genuine Damascus reveals unique microstructures and resilience born from traditional forging methods, unlike modern replicas.

Think of authentic Damascus as a fingerprint of craftsmanship, impossible to replicate perfectly.

By understanding these subtle yet critical differences, you’ll confidently navigate the market. This ensures your purchase embodies both the legendary strength and artistry that define true Damascus steel.

- Japanese Steel Knife Core, Super Sharp: SHAN ZU chef’s knife core is made of 10Cr15Mov Damascus…

- REAL Damascus Knife, not Lazer Etched: SHAN ZU Damascus chef knife layering sheets of carbon steel,…

- A total of 67 Layers Steel, Long-Lasting Use: SHAN ZU Damascus chef knife forged by 67 layer sheets…

Last update on 2026-03-02 / Affiliate links / Images from Amazon Product Advertising API